On Tuesday, March 29th we visited the St. Agatha School in Milton, visiting two 6th grade classes. In one room was Teddi (who ran our affiliated Genetics Afterschool Program last year) and myself, whilst in the other room were our two work studies Gabby and Zandria.

Today’s topic was engineering and the design process. During our introduction, when we asked about skills that engineers need, two very interesting answers came up. First – students said that engineers need confidence (this was my first time hearing this answer!) – a great answer (very interesting article on Engineering confidence / imposter syndrome here). Additionally, a student said “safety” – and this is a huge deal in engineering, safety practices and standards. Every lab on NEU’s campus has required safety standards and there’s a whole regulatory agency of the government dedicated to safety – OSHA. Plus – “safety engineer” is an actual career path itself.

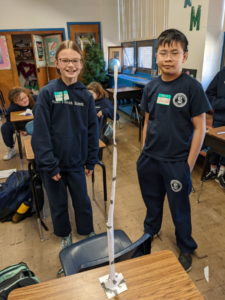

After looking at the Engineering Design Process (after roleplaying how to design a better alarm – we came up with a bed that launches you out of it), students became civil engineers and designed and built paper towers to be as tall as possible. Some incredible designs – in fact, we had two super tall towers – a 32 inch tower (seen here) and a 27 inch tower – the two tallest towers I’ve seen in at least 2 years.

After looking at the Engineering Design Process (after roleplaying how to design a better alarm – we came up with a bed that launches you out of it), students became civil engineers and designed and built paper towers to be as tall as possible. Some incredible designs – in fact, we had two super tall towers – a 32 inch tower (seen here) and a 27 inch tower – the two tallest towers I’ve seen in at least 2 years.

Next – students became environmental engineers – and designed and built wind turbines. Using a testing set-up, students were tasked with designing wind turbine blades to lift a weight as fast as possible. After tracking data in excel and calculating total energy generated, we discovered a couple things. First, short rotor arms were the best. Our testing set-up requires a connection point between the central hub and the turbine blade itself, unlike real turbine blades which are connected directly to the central hub of the turbine. The designs with shorter rotor arms in our case worked better due to the concentrated wind being generated by our narrow fan, which – with longer rotor arms, moved the actual pushing surface of the turbine blades beyond the edges of the wind.

In addition, our testing setup had an even symmetrical hub, meaning 4 bladed designs were the best, which is different than the real world, where 3 bladed designs are the best (Why 3 Blades?). Interestingly enough, technology has made blade-less turbine designs that vibrate with the wind possible, meaning the danger of birds flying into spinning blades is mitigated!

In addition, our testing setup had an even symmetrical hub, meaning 4 bladed designs were the best, which is different than the real world, where 3 bladed designs are the best (Why 3 Blades?). Interestingly enough, technology has made blade-less turbine designs that vibrate with the wind possible, meaning the danger of birds flying into spinning blades is mitigated!

The fact that surprised students the most is just how little energy a wind turbine by itself generates. This has to do with a combination of the inefficiencies in modern wind turbines (~75% efficient) and the fact that wind turbines can actually only perfectly capture 16/27 (59.3%) of the kinetic energy in wind (known as Betz’s law). With 15 mph wind, a wind turbine with 1 meter blades generates 48 watts of energy, less energy than a typical lightbulb requires (60 watts). Therefore, industrial wind turbines are enormous – the industry-average is blades 50 meters (164ft) long!  These can generate ~1.5 megawatts of electricity (or ~15 car engines). Therefore – modern wind turbines are set up in wind farms – massive collections of wind turbines. The largest in the USA (3rd largest in world) is the Alta Wind Energy Center in California, operating 600 turbines, whilst the largest in the world is the Gansu Wind Farm in China, operating over 7000 turbines.

These can generate ~1.5 megawatts of electricity (or ~15 car engines). Therefore – modern wind turbines are set up in wind farms – massive collections of wind turbines. The largest in the USA (3rd largest in world) is the Alta Wind Energy Center in California, operating 600 turbines, whilst the largest in the world is the Gansu Wind Farm in China, operating over 7000 turbines.